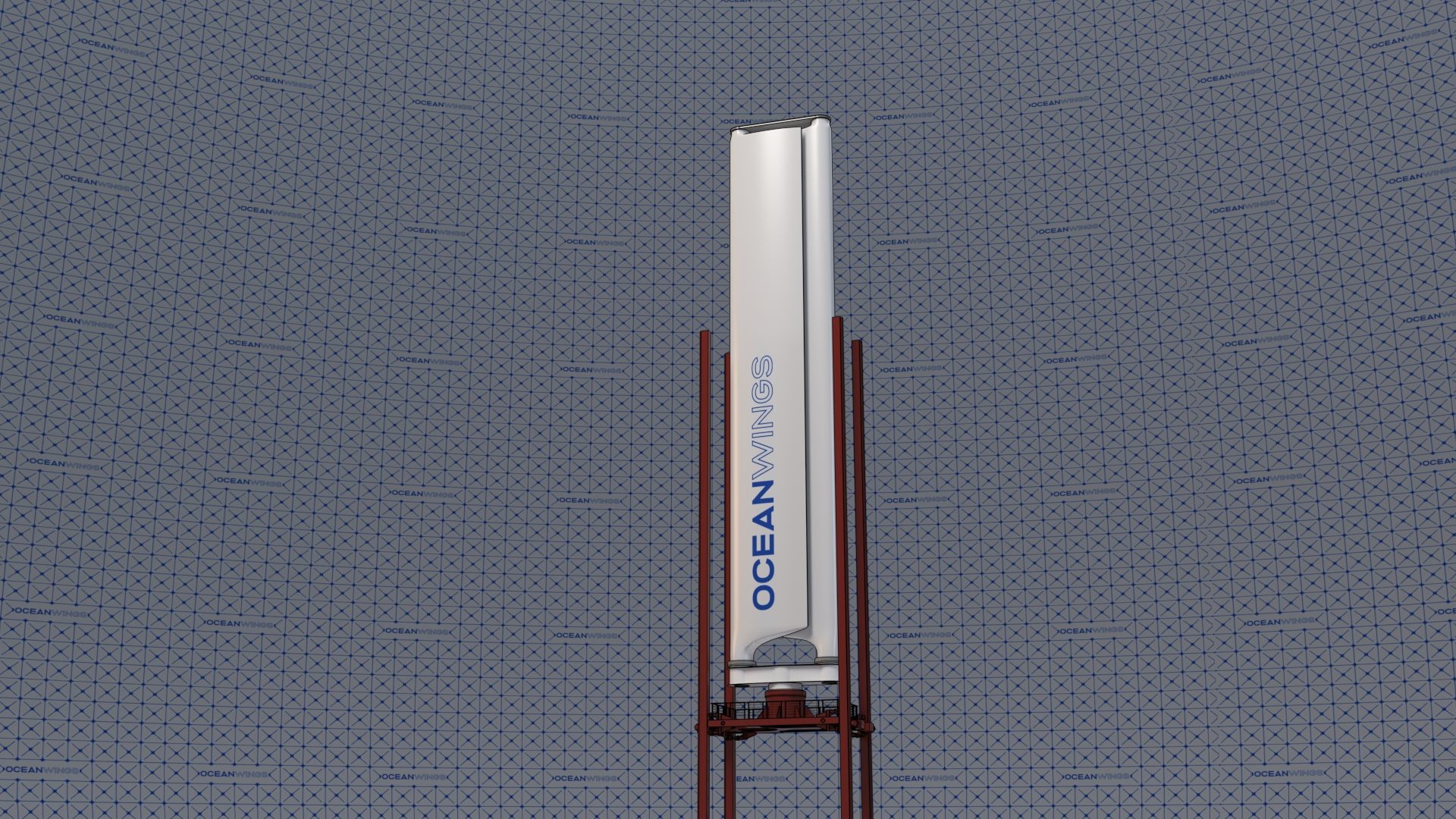

AYRO, a leader in Wind Assisted Ship Propulsion (WASP) systems, has introduced an expanded Wingsail portfolio designed to adapt to the cargo needs of ships of most types or size, despite vastly different requirements. Additionally, the company has rebranded as ‘OceanWings,’ with the announcement made at Posidonia 2024 in Athens today.

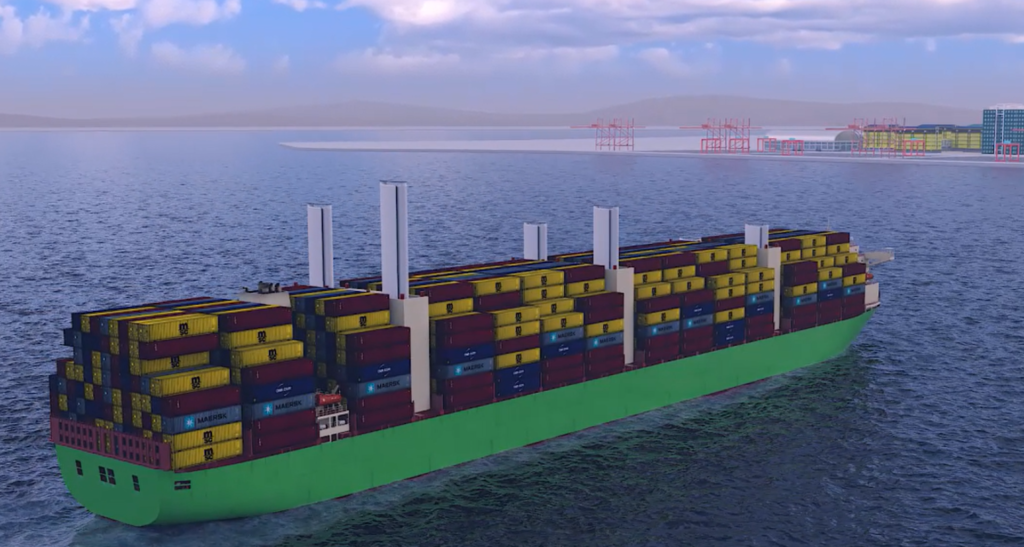

The rebranding follows a successful design, manufacturing and commercialization phase over the past six years, bookended in 2023 by the launch and subsequent commercial operations of the Canopée RORO cargo ship, equipped with 4 fuel saving OceanWings® Wingsails. The company is adopting the OceanWings branding as its sole company brand, to streamline communication as it evolves and expands its Wingsail portfolio to accommodate a more flexible, modular approach.

The rebranding follows a successful design, manufacturing and commercialization phase over the past six years, bookended in 2023 by the launch and subsequent commercial operations of the Canopée RORO cargo ship, equipped with 4 fuel saving OceanWings® Wingsails. The company is adopting the OceanWings branding as its sole company brand, to streamline communication as it evolves and expands its Wingsail portfolio to accommodate a more flexible, modular approach.

The new product range ensures the industry-leading fuel savings unlocked by OceanWings® and confirmed by the fuel savings measured in operations on Canopée, are now available to most shipowners, across multiple segments (including tankers, bulkers, PCTC, Cruise Ships) and ship sizes.

The new product range ensures the industry-leading fuel savings unlocked by OceanWings® and confirmed by the fuel savings measured in operations on Canopée, are now available to most shipowners, across multiple segments (including tankers, bulkers, PCTC, Cruise Ships) and ship sizes.

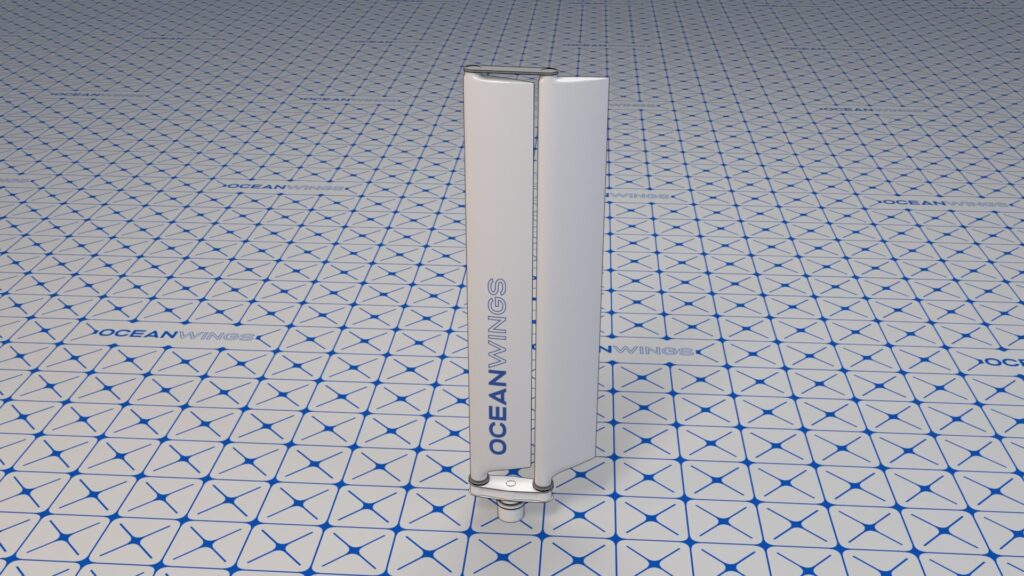

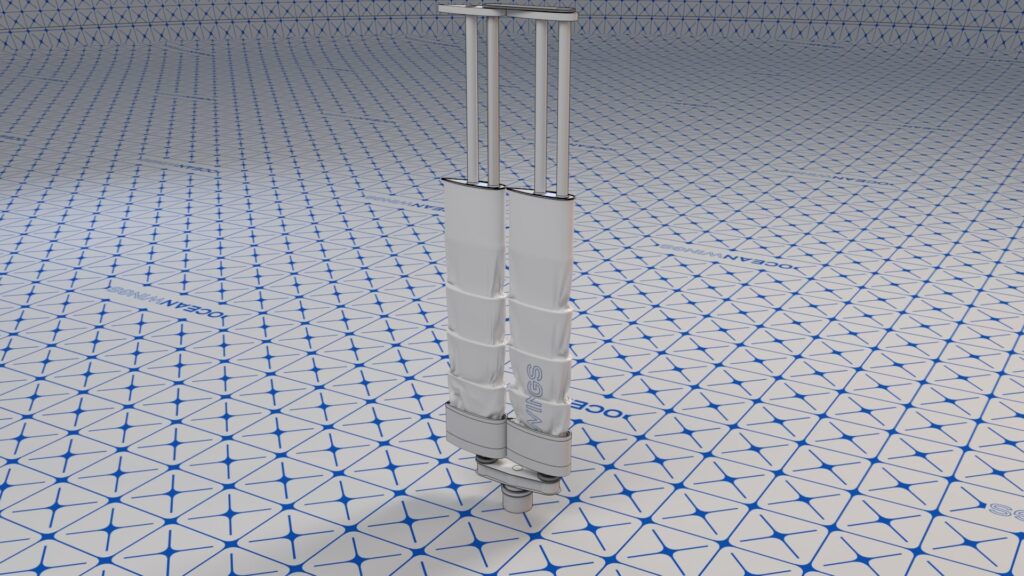

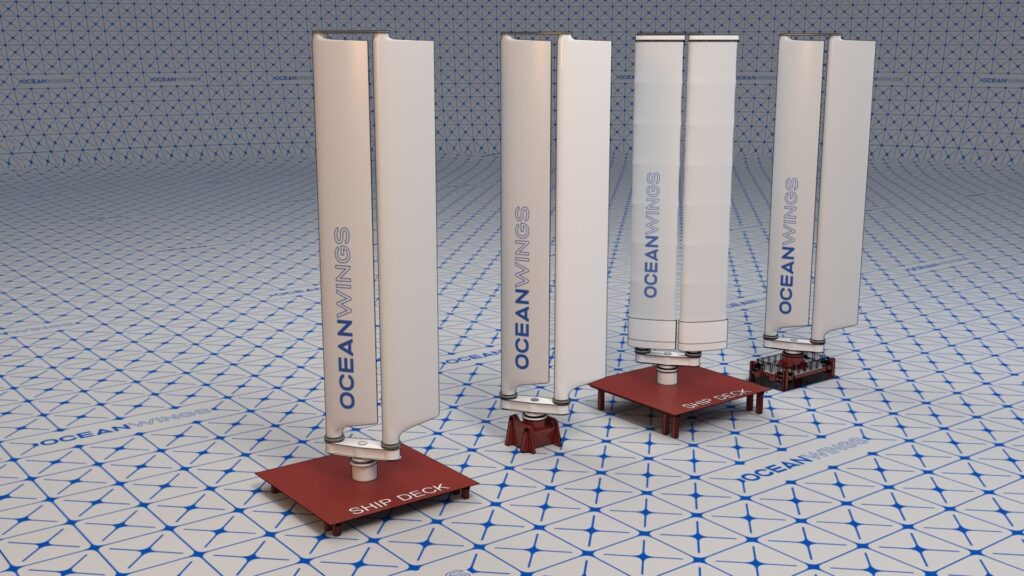

The semi-rigid and new rigid OceanWings® share the same unique ‘two flap variable camber’ design—including the Wingsail base and boom—which is already proven to deliver industry-leading fuel savings over most operational scenarios and environmental conditions. The OceanWings product range also features a “safety-by-design” flag mode, automatically protecting the OceanWings and the vessel when wind or sea conditions exceed specific thresholds.

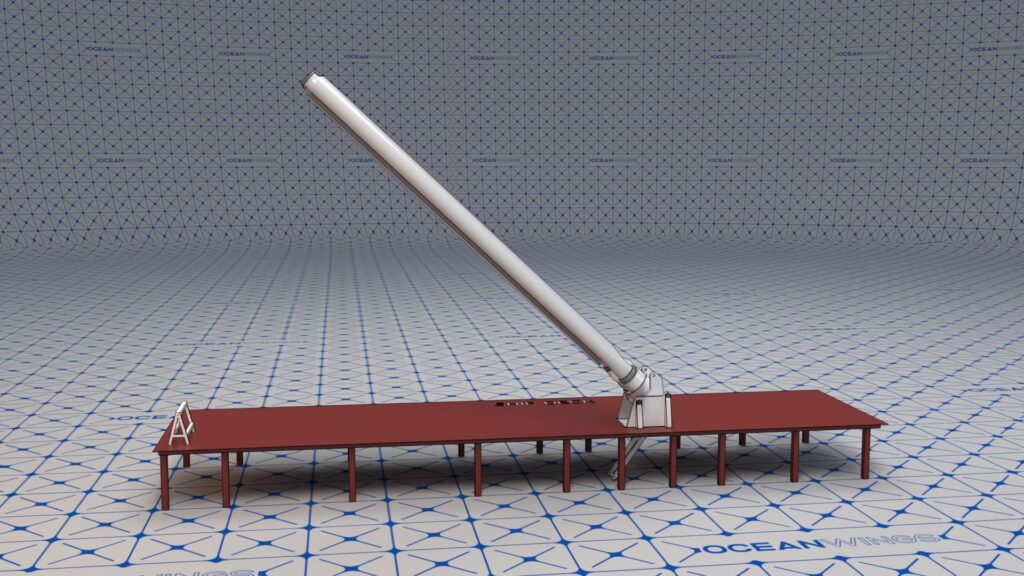

The OceanWings product range now also includes critical configuration options such as a tilt mechanism, to address air draft requirements, and an elevator mechanism specially designed for container ships to comply with their port operation constraints while minimizing the impact on container capacity. OceanWings® remains the only solution on the market offering a lowerable / reefable design, which is a critical feature for vessels where tilting is not an option.

The OceanWings product range now also includes critical configuration options such as a tilt mechanism, to address air draft requirements, and an elevator mechanism specially designed for container ships to comply with their port operation constraints while minimizing the impact on container capacity. OceanWings® remains the only solution on the market offering a lowerable / reefable design, which is a critical feature for vessels where tilting is not an option.

Rigid OceanWings® are made from the same modern composite materials following the same manufacturing processes as wind turbine blades. This provides advantages in resilience and lifespan, as well as leverages a global manufacturing infrastructure to drive competitive pricing and the ability to scale to large volumes. The new modular design also optimizes transportation and installation.

Rigid OceanWings® are made from the same modern composite materials following the same manufacturing processes as wind turbine blades. This provides advantages in resilience and lifespan, as well as leverages a global manufacturing infrastructure to drive competitive pricing and the ability to scale to large volumes. The new modular design also optimizes transportation and installation.

“The entire OceanWings product range is based on the same aerodynamic design that is now proven to deliver class-leading payback to shipowners, while adding more flexibility and integration options for newbuilds and retrofit,” adds Schalit. “In light of a rapidly expanding WASP market, we have also focused on improving our design and processes to be able to deliver faster and with consistent quality to our customers around the world.”

“The entire OceanWings product range is based on the same aerodynamic design that is now proven to deliver class-leading payback to shipowners, while adding more flexibility and integration options for newbuilds and retrofit,” adds Schalit. “In light of a rapidly expanding WASP market, we have also focused on improving our design and processes to be able to deliver faster and with consistent quality to our customers around the world.”