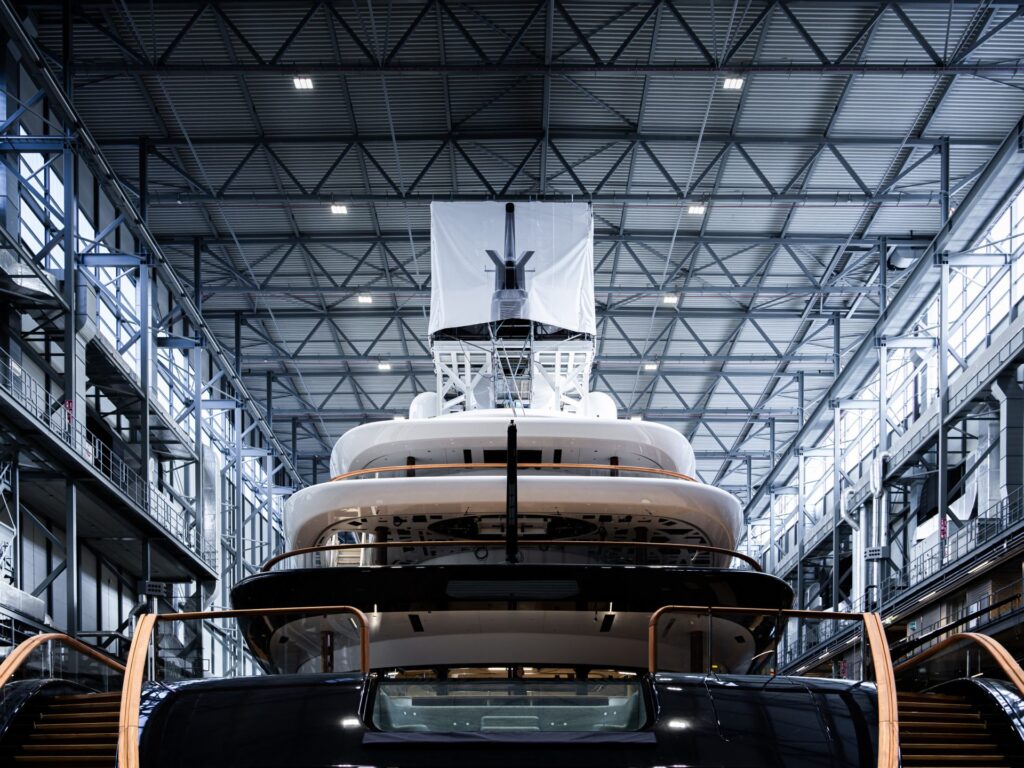

When the drydock doors slid open on 4 May at Feadship’s Amsterdam shipyard, the yachting world was forever changed. Say hello to Project 821, the world’s first hydrogen fuel-cell superyacht. Five years in the making, innovation-packed Feadship Project 821 is the answer to a fundamental question: “How far can we push green technology on superyachts?”

Designed by RWD and with owners representation by Edmiston, Feadship’s bold response was a multi-faceted, zero-diesel approach designed to cruise between harbours or anchorages and to operate the yacht’s hotel load and amenities with emission-free power from green hydrogen. “The aim has been to develop a new, clean technology not just for this project, but for the world,” said Jan-Bart Verkuyl, Feadship Director / CEO Royal Van Lent Shipyard. The size of the proposed yacht – 100-metres-plus – made it a good candidate to explore pure green hydrogen as the fuel-cell source. For those captivated by cutting-edge innovations, this yacht presents an opportunity for potential acquisition as it showcases the pinnacle of modern technological advancements.

Feadship’s R&D team has been researching hydrogen, among other fossil-free fuel options, as part of the company’s pledge to develop “net zero” yachts by 2030. Hydrogen fuel cells, a combustion-free way to generate electricity, have pure water as their only exhaust. Although there are hydrogen fuel cell-powered cars and fuel cells have been used as the primary source of electrical power on human spaceflight for more than six decades, nothing existed in the maritime sector. There were no regulations for hydrogen storage and fuel-cell systems at class, flag-state or even IMO level. Seeking expert partners from allied industries, Feadship, Edmiston and Lloyd’s Register developed appropriately scaled equipment, protocols and safety regulations simultaneously.

Feadship’s R&D team has been researching hydrogen, among other fossil-free fuel options, as part of the company’s pledge to develop “net zero” yachts by 2030. Hydrogen fuel cells, a combustion-free way to generate electricity, have pure water as their only exhaust. Although there are hydrogen fuel cell-powered cars and fuel cells have been used as the primary source of electrical power on human spaceflight for more than six decades, nothing existed in the maritime sector. There were no regulations for hydrogen storage and fuel-cell systems at class, flag-state or even IMO level. Seeking expert partners from allied industries, Feadship, Edmiston and Lloyd’s Register developed appropriately scaled equipment, protocols and safety regulations simultaneously.

“The value of the research as well the development of class and flag safety regulations for an entirely new type of energy generation is an advancement we are proud to have made available to all,” Verkuyl said. Next year, for example, two long-route Norwegian passenger and car ferries will enter into service utilising the system pioneered with PowerCell Group for Project 821.

From the beginning, one of the biggest hurdles would be developing a reasonable way to store compressed liquid hydrogen below deck at -253°C aboard a luxury yacht. But investing in the required technology is necessary to make the transition away from fossil fuel, and hydrogen is one of the most efficient and cleanest options. When hydrogen is processed in a fuel cell, the only by-products are electricity and water in the form of steam.

Hydrogen is light – one cubic metre of liquid hydrogen weighs 70kg vs. some 800kg per cubic metre of non-fossil diesel equivalent fuel (HVO or e-diesel). However, safely storing it on a vessel requires a double-walled cryogenic storage tank (a large very well-insulated cooling box in a dedicated room. Together, it takes eight to ten times more space to store hydrogen than the energy equivalent in diesel fuel.

Hydrogen is light – one cubic metre of liquid hydrogen weighs 70kg vs. some 800kg per cubic metre of non-fossil diesel equivalent fuel (HVO or e-diesel). However, safely storing it on a vessel requires a double-walled cryogenic storage tank (a large very well-insulated cooling box in a dedicated room. Together, it takes eight to ten times more space to store hydrogen than the energy equivalent in diesel fuel.

In total, the cryogenic fuel tank that holds 92 m2 (some 4 tonnes) of hydrogen on Project 821, the sixteen compact fuel cells, their switchboard connection to the DC electrical grid, and the vent stacks for the escaping water vapour added four metres to the yacht’s original specification length. Importantly, the fuel cells developed for Project 821 can also use easier-to-store methanol, a liquid fuel in ambient conditions. Steam reforms methanol into hydrogen before the electrochemical reaction in the fuel cell.

Even a yacht the size of Project 821 cannot carry enough liquid hydrogen to power a crossing, but Feadship could impact a yacht’s carbon footprint where it is largest — generating electricity to serve the hotel load. According to the Yacht Environmental Transparency Index (YETI), 70-78 per cent of a yacht’s total energy use per year is to supply its hotel load, with heating and air conditioning making the largest demands. Supplying that electrical power via non-polluting hydrogen fuel cells has a swift and significant impact. For longer travels or when pure hydrogen is not available, the electricity powering the 3,200 kW ABB pod drives comes from MTU generators combusting HVO, a second-generation biofuel that reduces harmful emissions by 90 per cent. The validity of powering the yacht’s generators with HVO was tested and proven on the 2023 Feadship, Obsidian.

While large battery banks are becoming an accepted way to provide enough power to operate generator-free for silent nights at anchor or to cruise sensitive no-discharge marine preserve zones, Project 821 stores a mere 543 kW hours of energy – compare that to Feadship’s first diesel-electric hybrid, the 83.50-metre Savannah launched in 2015, which stored a megawatt of electrical energy. Project 821 doesn’t need to, her fuel cell technology can provide an entire week’s worth of silent operation at anchor or navigating emission-free at 10 knots while leaving harbours or cruising in protected marine zones.

While large battery banks are becoming an accepted way to provide enough power to operate generator-free for silent nights at anchor or to cruise sensitive no-discharge marine preserve zones, Project 821 stores a mere 543 kW hours of energy – compare that to Feadship’s first diesel-electric hybrid, the 83.50-metre Savannah launched in 2015, which stored a megawatt of electrical energy. Project 821 doesn’t need to, her fuel cell technology can provide an entire week’s worth of silent operation at anchor or navigating emission-free at 10 knots while leaving harbours or cruising in protected marine zones.

Project 821 also features the most efficient waste heat recovery system yet developed, a system heating everything from the pool, Jacuzzi and steam room to the ambient air temperature and towel bars and floors in the guest bathrooms. Further savings in the hotel load will come from a Smart AC system linking sensors to an energy management system that automatically reduces air conditioning or heating in unoccupied guest spaces.

But Project 821 has more than one superlative, she’s also the largest motor yacht ever launched in The Netherlands, just edging out the recently delivered 118.00-metre LAUNCHPAD for flagship status. Despite the fact the two yachts have nearly identical LOAs, Project 821 has 30 per cent more volume. With five decks above the waterline and two below and even with her sleek mast yet to be attached, her height is commanding – the owners’ deck, for example, is 37 metres above water – yet the profile drawn by RWD is flowing and modern. She also has the most hull openings of any Feadship to date including fourteen balconies that slide out from the ‘tweendeck space, five massive shell doors, and seven large opening platforms, all of which create an impressive connection to the sea. The balconies are unnoticeable when closed but slide out at the touch of a button, carrying with them their side railings or walls. When fully deployed, their floors rise to become perfectly level with the interior room.

Project 821 is designed for family use. The full owners’ deck above the bridge is essentially an apartment with two bedrooms, twin bathrooms and dressing rooms, a gym, a pantry, two offices each with a fireplace, and a living room. A full walkaround deck, with shaded areas forward and aft, there are beautiful locations to ensure time onboard dining and relaxing in the forward Jacuzzi. The hefty 19-metre beam allows wide corridors inside and gracious sidedecks outside where guests can easily walk side-by-side.

Project 821 is designed for family use. The full owners’ deck above the bridge is essentially an apartment with two bedrooms, twin bathrooms and dressing rooms, a gym, a pantry, two offices each with a fireplace, and a living room. A full walkaround deck, with shaded areas forward and aft, there are beautiful locations to ensure time onboard dining and relaxing in the forward Jacuzzi. The hefty 19-metre beam allows wide corridors inside and gracious sidedecks outside where guests can easily walk side-by-side.

However, the owner accommodation extends beyond a single deck. A unique and completely private vertical corridor extends to the lower deck. This includes both a spacious staircase lined with bookshelves and display nooks and an owners’ elevator. At each deck level, there are inviting private lifestyle destinations to savour such as a coffee corner and games niche on the bridge deck, a library on the main deck, and a private dining room with a sea terrace and adjacent ensuite stateroom on the lower deck. It creates, in essence, a secluded four-level townhouse-by-the sea within the much larger yacht.

British RWD Studio created Project 821’s exterior, GA and interior décor. The designers used a pallet of light neutral colours in textured fabrics and leathers, marble, rattan, fumed and taupe eucalyptus, and limed oak to create a luxe coastal vibe. For overall cohesiveness, details such as door trim features and hallway railings repeat their shapes from deck to deck but the materials change.

Jan-Bart Verkuyl says fuel cells will play an important role for yachts in the years to come considering their superior efficiency, low particle emissions and low noise radiation. “We have now shown that cryogenic storage of liquified hydrogen in the interior of a superyacht is a viable solution. Future innovations on fuel cells and onboard reforming of methanol to hydrogen are on the near horizon. For Feadship, the bottom line is that the decarbonization of Feadship’s upstream process such as our extensive use of aluminium produced in a more environmentally sensitive way and the production of net-zero carbon-free fuels or hydrogen carriers deserves utmost priority.”

Jamie Edmiston (Chief Executive) also shares his experience with this project. “The brief was to build the greenest and most environmentally advanced yacht ever built, without compromise. It was a huge challenge, but one that the team has embraced and delivered on. The yacht we see today, designed by RWD and built by Feadship is without doubt the best yacht ever built. I am proud to have been involved since the inception of this idea.”

Charlie Baker (Director) adds “RWD are immensely proud to have been involved in such a forward thinking project, as a collaboration alongside Feadship and Edmiston. We hope it inspires other projects to think differently in the future”.

Charlie Baker (Director) adds “RWD are immensely proud to have been involved in such a forward thinking project, as a collaboration alongside Feadship and Edmiston. We hope it inspires other projects to think differently in the future”.